Q: What are the important thing elements to consider when choosing a prototype PCB assembly supplier? A: A very powerful components are their capabilities, quality, supply, responsiveness, and pricing. Search for a producer with experience assembling complex board designs with microcomponents. They should have glorious course of controls and inspection to make sure reliable assembly quality. Fast turnaround times are perfect for verifying your design rapidly. Good venture administration and engineering assist are also useful. Q: What are some leading PCB assembly equipment firms? A: Juki, Yamaha, Panasonic Factory Solutions, Fuji, ASM, and PCB (http://www.drugoffice.gov.hk/gb/unigb/www.hitechcircuits.com) Universal Instruments are a few of the highest electronics assembly gear manufacturers. They make placement machines, soldering methods, inspection tools, and different assembly expertise. High-performing gear is crucial for precision manufacturing. Q: How long does prototype PCB assembly usually take? A: Assembly lead times vary from 24 hours for simple boards to 10 days or more for very advanced designs. Typical turnaround for small prototype orders is 3 to 5 days. The more layers, elements, and better the density, the extra time is required for quality meeting.

Q: What are the important thing elements to consider when choosing a prototype PCB assembly supplier? A: A very powerful components are their capabilities, quality, supply, responsiveness, and pricing. Search for a producer with experience assembling complex board designs with microcomponents. They should have glorious course of controls and inspection to make sure reliable assembly quality. Fast turnaround times are perfect for verifying your design rapidly. Good venture administration and engineering assist are also useful. Q: What are some leading PCB assembly equipment firms? A: Juki, Yamaha, Panasonic Factory Solutions, Fuji, ASM, and PCB (http://www.drugoffice.gov.hk/gb/unigb/www.hitechcircuits.com) Universal Instruments are a few of the highest electronics assembly gear manufacturers. They make placement machines, soldering methods, inspection tools, and different assembly expertise. High-performing gear is crucial for precision manufacturing. Q: How long does prototype PCB assembly usually take? A: Assembly lead times vary from 24 hours for simple boards to 10 days or more for very advanced designs. Typical turnaround for small prototype orders is 3 to 5 days. The more layers, elements, and better the density, the extra time is required for quality meeting.

Discussing your particular project with manufacturers will provide correct delivery estimates. Q: What are some alternate options to having my prototype board assembled? A: Some options besides skilled meeting are hand soldering the PCB your self or using a interest choose-and-place machine. However, these rarely match the standard and reliability of economic manufacturing. Engineers typically hand assemble a couple of initial boards then change to skilled meeting once the design is more mature. Q: Does every element on my BOM have to be validated earlier than starting PCB assembly? A: While full BOM validation is really useful, it’s not mandatory. For prototypes, some substitute elements may be quickly used if most popular components are unavailable. Any substitutes ought to be functionally similar. Manufacturers can sometimes procure over 90% of specified parts with their giant supplier networks. Choosing the proper PCB assembly accomplice is a key step in transforming your design from prototype to completed product. The manufacturers profiled provide the expertise, capabilities, quality, and speedy delivery required to assemble today’s complicated boards. They provide invaluable help to confirm circuit designs and speed up projects from concept to manufacturing.

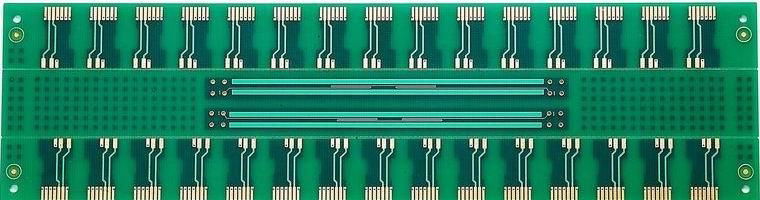

In response to the number of digital board layers, it can be divided into single-sided, double-layer, four-layer, six-layer, and other multilayer circuit boards. And proceed to develop within the path of excessive precision, high density, and excessive reliability. Continuously shrinking volume, decreasing prices, and bettering efficiency have enabled printed circuit boards to take care of strong vitality in the event of future electronic merchandise. The future growth trend of PWB manufacturing technology is to develop within the course of excessive density, excessive precision, superb aperture, wonderful wire, small pitch, high reliability, multilayer, excessive-speed transmission, lightweight, and thinness in performance. The one layer is on an insulating substrate with a thickness of 0.2-5mm, only one floor is lined with copper foil, and a printed circuit is formed on the substrate by printing and etching. The single panel is easy to manufacture and simple to assemble. The double sided boards are printed circuits on each sides of an insulating substrate with a thickness of 0.2-5mm. It is appropriate for digital products with normal requirements, reminiscent of digital computers, electronic instruments and meters.

One among a very powerful components of the digital industry in the present day is the Printed Circuit Board or PCB as we commonly realize it. Lately, PCB manufacturers have taken charge of complying with the most recent technological developments with a view to provide you with better and more practical printed circuit boards, designs and different assembling procedures to serve numerous industries. Regardless of whatever your budgetary limitations are, there are some basic necessities that must be fulfilled in order to pick out and work with the correct PCB producer. Provided that it’s a daunting job to seek for the most effective PCB manufacturers and suppliers available in the market, there are countless companies shamming folks for the sake of earning money. To avoid getting caught in such type of situations, it’s essential to follow sure ideas to pick out the proper PBC manufacturer. Start off by getting a listing of genuine PCB sellers out there. You might be most likely to get pertinent data from business commerce shows.

One among a very powerful components of the digital industry in the present day is the Printed Circuit Board or PCB as we commonly realize it. Lately, PCB manufacturers have taken charge of complying with the most recent technological developments with a view to provide you with better and more practical printed circuit boards, designs and different assembling procedures to serve numerous industries. Regardless of whatever your budgetary limitations are, there are some basic necessities that must be fulfilled in order to pick out and work with the correct PCB producer. Provided that it’s a daunting job to seek for the most effective PCB manufacturers and suppliers available in the market, there are countless companies shamming folks for the sake of earning money. To avoid getting caught in such type of situations, it’s essential to follow sure ideas to pick out the proper PBC manufacturer. Start off by getting a listing of genuine PCB sellers out there. You might be most likely to get pertinent data from business commerce shows. Want the benefits of a Pilates workout at residence, with out the inconvenience and expense of a traditional studio experience? Then consider one of those finest Pilates reformers for residence fitness. We’ve hand-picked options for each budget and potential, whether or not you’re a total newbie or highly skilled. Reformers aren’t fairly as compact and portable as Pilates chairs, but each widespread pieces of gear present an important full-body workout. If you loved this information and you wish to receive much more information about

Want the benefits of a Pilates workout at residence, with out the inconvenience and expense of a traditional studio experience? Then consider one of those finest Pilates reformers for residence fitness. We’ve hand-picked options for each budget and potential, whether or not you’re a total newbie or highly skilled. Reformers aren’t fairly as compact and portable as Pilates chairs, but each widespread pieces of gear present an important full-body workout. If you loved this information and you wish to receive much more information about  Wall mounted retractable belt limitations are an efficient and efficient manner to manage crowds or guide individuals in your retail area, airport, stadium, warehouse, theater or different venue. These versatile obstacles are the proper resolution for managing foot traffic and creating designated areas for maintenance or work. And one of the best part? You could find a wide variety of choices at Crowd Control Store, including magnetic and non-magnetic wall mounted retractable belt limitations. With their small footprint, these limitations save on ground space while still providing a secure and easy approach to create barriers. So whether or not you want to dam off aisles, prohibit entry to certain areas, or management crowds at occasions, wall mounted retractable belt boundaries are the method to go. Trust us, your crowd management game will never be the same! Understanding the fundamentals: What are Magnetic and Non-Magnetic Multi-Surface Wall Mount Barriers? Wall mounted limitations are an important device for controlling crowds and managing foot visitors in numerous areas.

Wall mounted retractable belt limitations are an efficient and efficient manner to manage crowds or guide individuals in your retail area, airport, stadium, warehouse, theater or different venue. These versatile obstacles are the proper resolution for managing foot traffic and creating designated areas for maintenance or work. And one of the best part? You could find a wide variety of choices at Crowd Control Store, including magnetic and non-magnetic wall mounted retractable belt limitations. With their small footprint, these limitations save on ground space while still providing a secure and easy approach to create barriers. So whether or not you want to dam off aisles, prohibit entry to certain areas, or management crowds at occasions, wall mounted retractable belt boundaries are the method to go. Trust us, your crowd management game will never be the same! Understanding the fundamentals: What are Magnetic and Non-Magnetic Multi-Surface Wall Mount Barriers? Wall mounted limitations are an important device for controlling crowds and managing foot visitors in numerous areas.