The PCB board is generally used in electronics as a base material which is often made up of composite epoxy, fiberglass or any composite materials. As you understand that they are primarily associated with computer systems, various kinds of those boards are utilized in different fields additionally, depending upon the requirement. These are made up of fabric which will be flexible as well as movable. If you have any kind of concerns pertaining to where and ways to utilize printed circuit board cost, you can contact us at the website. The Flex-rigid circuit board prices are usually higher due to the fabrication process. It has extra advantages over the rigid ones. They can be wrapped round corners. The weight also decreases since it is a single-layered board. It is utilized in materials which wants waterproofing, corrosion-resistant and shock proofing. They’re particularly designed to transmit indicators which are a couple of gigahertz. The Flex-inflexible circuit boards made up of high-frequency boards which include polyphenylene oxide (PPO) resin, glass-reinforced epoxy laminate, and Teflon. If a board is made up of a single layer of fabric it is known as single-layered boards.

Only one aspect of the board is made up of steel. As you recognize that copper is an electrical conductor, so it’s used within the coating. After the coating with the copper is done, then a protective mask is applied and above that silkscreen. They have their varied components and circuit placed on one facet only. These boards are easy to design and the manufacturing price can be fairly low if made in excessive volumes. When the board is made up of a thin layer of material corresponding to copper on each sides of the boards is known as double layered boards. The circuit on one facet of the board connects the opposite facet of the board by drilling holes. They are often connected in one other approach additionally which is through surface mounting. In this methodology, fairly much less area is used as small leads are directly soldered into the board. This enables the board to supply extra functions by growing the pace and also decreases the load. This is made up of a cloth that prevents the board from twisting. A pc motherboard is the most effective instance of the inflexible boards. It’s designed to allocate electricity and permitting them to speak between the various components of the computer. They comprise the most important share in the PCB markets. These inflexible boards could be anything from a single-layered to seven to eight layered multi-layered inflexible boards. Instead of using fiberglass they are made up of copper or aluminum boards. They are surroundings-pleasant and are inexpensive. They can be simply recycled and is also a better method to converse energy. Aluminum boards are much more durable in comparison with different supplies that reduce the injury that’s induced throughout installation and shipping.

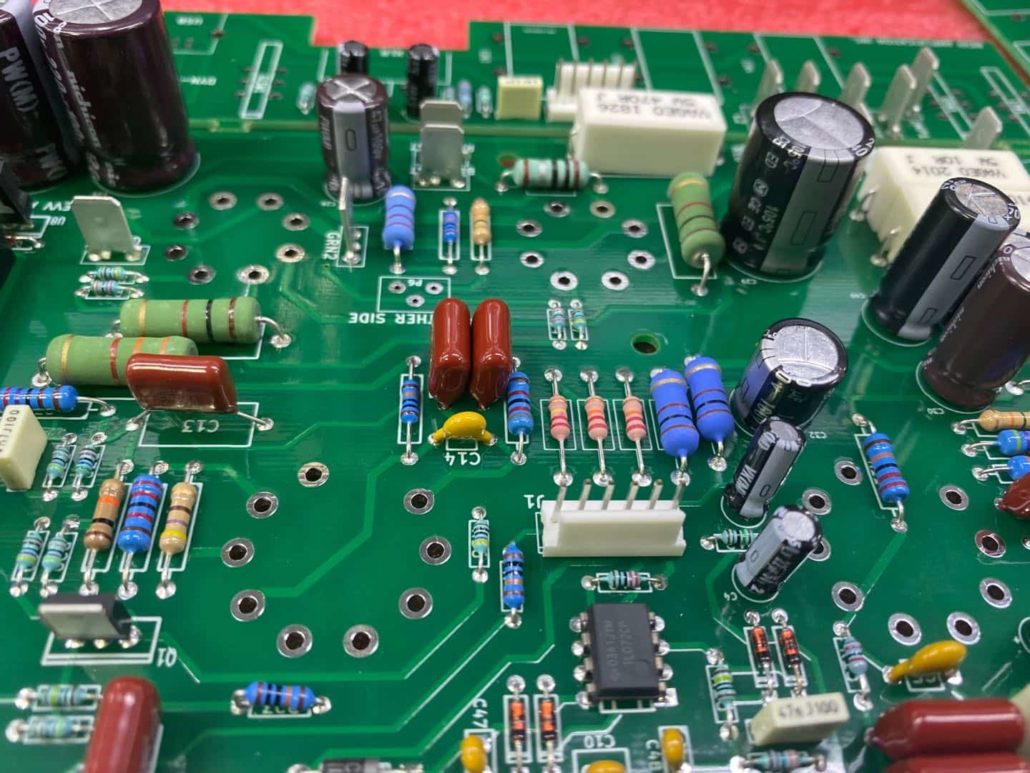

The world is rising at a very fast pace in terms of fashionable technology and the consequences are easily on our daily lives. Our life model has modified drastically. This technological development has introduced many advance tools on this planet that we did not imagine about 10 years ago. The core of these tools is electronics engineering and the nucleus is the Printed Circuit Boards (PCBs). The PCB is something that is normally green in shade and is a rigid physique that holds varied electronic parts on it. These parts are soldered upon the PCBs in the process called “PCB Assembly” or PCBA. The PCB is composed of a substrate that is made of fiber glass, the elements, the copper layer that makes the traces, holes wherein elements are fitted and layers that may be inside layer and outer layers. At RayPCB we can ship as much as 1-36 layers for multilayer PCB prototypes and 1-10 layers for multilayer PCBs for mass production.

For single sided PCB and double sided PCBs, the outer layers current however no internal layer. The pcb substrate and elements are insulated with solder mask and held along with epoxy resin. This solder mask may be green, blue or printed circuit board cost crimson in color as commonly present in PCB colors. The solder mask will allow the parts to avoid quick circuit with tracks or different elements. The copper traces are used to carry digital signals from one level to the other on the PCB. These indicators can be high speed digital signals or discrete analog signals. These traces might be made thick to hold power / electricity to power up components. In most of the PCBs that are made to produce high voltage or current, there is a separate airplane of floor connection. The electronic parts on top layer are related to internal GND aircraft or inside signals layer via “Vias”.

The components are assembled on the PCB to permit the PCB to operate as it’s designed. A very powerful factor is the PCB performance. The PCB may not work even if a tiny SMT resistor just isn’t properly positioned or even if a small observe is reduce from the PCB producer. So it is very important the elements are assembled in correct method. The PCB when components are assembled is known as PCBA or Assembled PCB. The performance of PCBs will be advanced or easy relying on the specifications described by the shopper or pcb assembly user. The PCB sizes are additionally different depends upon necessities. The PCB assembly course of has automated and manual course of which we’ll talk about. As we described above there are a number of signal layers between the outer layers. Now we are going to talk about on the sorts of outer layers and functionality. 1- Substrate: It is the inflexible board fabricated from FR-four materials onto which the components are “stuffed” or soldered.

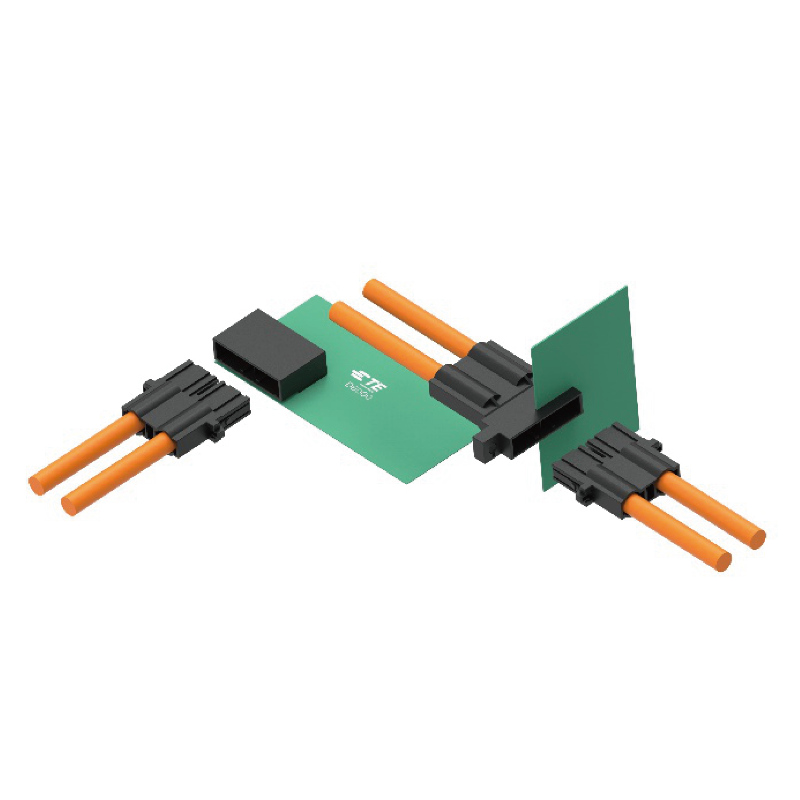

So, if in case you have an electronics project where you will have multiple circuit boards, then you’ll additionally must do something to energy them up. To energy up all of the circuit boards in a gadget, you’ll have to use board-to-board connectors, which you’ll consider as a bridge. It may possibly bridge your PCBs to energy them up. In this article, we’ll spotlight all the pieces that you must learn about board-to-board connectors. What is a Board-to-board Connector? When you work on an electronics venture that has several circuit boards, you also must power them up. An clever approach to give power to them is to use a board-to-board connector. It’s an electronic element that may act as a bridge to attach all of the circuit boards and provide them electricity. With a board-to-board connector, you may say goodbye to all of the trouble of advanced wiring and engineering, and you may get pleasure from a robust manufacturing course of.

So, if in case you have an electronics project where you will have multiple circuit boards, then you’ll additionally must do something to energy them up. To energy up all of the circuit boards in a gadget, you’ll have to use board-to-board connectors, which you’ll consider as a bridge. It may possibly bridge your PCBs to energy them up. In this article, we’ll spotlight all the pieces that you must learn about board-to-board connectors. What is a Board-to-board Connector? When you work on an electronics venture that has several circuit boards, you also must power them up. An clever approach to give power to them is to use a board-to-board connector. It’s an electronic element that may act as a bridge to attach all of the circuit boards and provide them electricity. With a board-to-board connector, you may say goodbye to all of the trouble of advanced wiring and engineering, and you may get pleasure from a robust manufacturing course of.

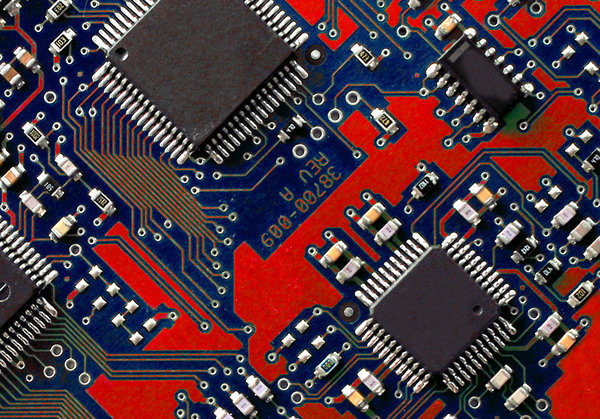

What are the Various kinds of PCB Designing? What do you truly mean by PCB? A printed circuit board (PCB) is an digital assembly that makes use of copper conductors to create electrical connections between totally different parts. Printed circuit boards present mechanical support for digital parts in the device to mount in an enclosure. However, the structures of PCB are fairly tough to understand. It is best to undoubtedly go for PCB Designing Training in Noida for a greater understanding of its construction. A printed circuit board design includes a sure set of steps that align with the manufacturing course of, built-in circuit packaging, and lastly the structure of the naked circuit board. Conductive options on printed circuit boards consist of copper traces, pads, and conductive planes. The mechanical structure is made up of insulating materials coating between totally different layers of conductors. A non-conductive solder mask, plates and covers the overall structure. Further, a silk screen material printing is finished on high of the solder mask to offer a legend for digital components.

What are the Various kinds of PCB Designing? What do you truly mean by PCB? A printed circuit board (PCB) is an digital assembly that makes use of copper conductors to create electrical connections between totally different parts. Printed circuit boards present mechanical support for digital parts in the device to mount in an enclosure. However, the structures of PCB are fairly tough to understand. It is best to undoubtedly go for PCB Designing Training in Noida for a greater understanding of its construction. A printed circuit board design includes a sure set of steps that align with the manufacturing course of, built-in circuit packaging, and lastly the structure of the naked circuit board. Conductive options on printed circuit boards consist of copper traces, pads, and conductive planes. The mechanical structure is made up of insulating materials coating between totally different layers of conductors. A non-conductive solder mask, plates and covers the overall structure. Further, a silk screen material printing is finished on high of the solder mask to offer a legend for digital components. After completing the fabrication steps, the naked board is distributed into printed circuit board assembly. Where elements soldering takes place and lastly the testing strategy of PCB takes place. The printed circuit board design has grown immensely in the electronics business. PCBs play an vital function in providing electrical interconnections between elements. To supplies inflexible help to carry components and a compact bundle to combine into an end product. Even the most fundamental circuit board wants a really carefully designing using specialised software packages. For every specific requirement, there is a sure sort of design out there. Single-sided – This board solely consists of elements mounting on a single surface. The again floor is usually absolutely copper (floor) and contains coating with a solder mask. Double-sided – This sort of circuit board has elements mounting on both surfaces. Each floor is defining a signal layer in the PCB stack-up, where the surfaces contain traces that carry alerts between elements. Multi-layer PCBs – These boards have conductors on internal layers that usually carry electrical signals between parts, or the interior layers could be conductive airplane layers.

After completing the fabrication steps, the naked board is distributed into printed circuit board assembly. Where elements soldering takes place and lastly the testing strategy of PCB takes place. The printed circuit board design has grown immensely in the electronics business. PCBs play an vital function in providing electrical interconnections between elements. To supplies inflexible help to carry components and a compact bundle to combine into an end product. Even the most fundamental circuit board wants a really carefully designing using specialised software packages. For every specific requirement, there is a sure sort of design out there. Single-sided – This board solely consists of elements mounting on a single surface. The again floor is usually absolutely copper (floor) and contains coating with a solder mask. Double-sided – This sort of circuit board has elements mounting on both surfaces. Each floor is defining a signal layer in the PCB stack-up, where the surfaces contain traces that carry alerts between elements. Multi-layer PCBs – These boards have conductors on internal layers that usually carry electrical signals between parts, or the interior layers could be conductive airplane layers. There are important decisions and concerns to make for pcba a profitable inflexible-flex PCB design process at an early stage. These are essential should you need to keep up its reliability and reduce costs. Are you a rigid-flex PCB designer in search of some design rules? This article is for you. What’s Rigid-Flex PCB? Rigid-Flex PCB is a board that combines inflexible board technologies and flexible circuits. The manufacturing process tends to be similar to a traditional hardboard circuit, however some layers are versatile circuitry running throughout the hardboard. Many inflexible-flex boards have multiple versatile circuit substrates layers attached to both a number of inflexible boards. This can also be internally or externally relying n the type of design used in the applying. The versatile circuit substrates are designed to maintain a constant state formed into flexed curves throughout set up or manufacturing. Rigid-flex PCB designs are more challenging than the standard rigid board surroundings because the boards are made in a 3D house with greater spatial efficiency.

There are important decisions and concerns to make for pcba a profitable inflexible-flex PCB design process at an early stage. These are essential should you need to keep up its reliability and reduce costs. Are you a rigid-flex PCB designer in search of some design rules? This article is for you. What’s Rigid-Flex PCB? Rigid-Flex PCB is a board that combines inflexible board technologies and flexible circuits. The manufacturing process tends to be similar to a traditional hardboard circuit, however some layers are versatile circuitry running throughout the hardboard. Many inflexible-flex boards have multiple versatile circuit substrates layers attached to both a number of inflexible boards. This can also be internally or externally relying n the type of design used in the applying. The versatile circuit substrates are designed to maintain a constant state formed into flexed curves throughout set up or manufacturing. Rigid-flex PCB designs are more challenging than the standard rigid board surroundings because the boards are made in a 3D house with greater spatial efficiency. Since it is attainable to design in three dimensions, it is simple for designers to twist, fold or roll the flexible substrates to achieve the specified closing form. The trendy expertise is properly improved in the case of the production of large-scale portions PCB assembly and PCB fabrication or manufacturing of a inflexible-flex prototype. The flex PCB course of is good in overcoming weight and space issues. Careful consideration of inflexible-flex options and correct assessment of the assorted options available is understood to have important benefits. The PCB fabricator is used early through the design course of to guarantee that the design and PCBA fabrication parts are in coordination and account for final product variations. The Rigid-flex PCB manufacturing process is advanced and time-consuming compared to inflexible board fabrication. Rigid-flex assembly flexible elements have completely different handling, soldering processes, and etching than the inflexible FR4 Boards. Maximizing house usually will increase the probabilities of decrease count in components.

Since it is attainable to design in three dimensions, it is simple for designers to twist, fold or roll the flexible substrates to achieve the specified closing form. The trendy expertise is properly improved in the case of the production of large-scale portions PCB assembly and PCB fabrication or manufacturing of a inflexible-flex prototype. The flex PCB course of is good in overcoming weight and space issues. Careful consideration of inflexible-flex options and correct assessment of the assorted options available is understood to have important benefits. The PCB fabricator is used early through the design course of to guarantee that the design and PCBA fabrication parts are in coordination and account for final product variations. The Rigid-flex PCB manufacturing process is advanced and time-consuming compared to inflexible board fabrication. Rigid-flex assembly flexible elements have completely different handling, soldering processes, and etching than the inflexible FR4 Boards. Maximizing house usually will increase the probabilities of decrease count in components.

The PCB pins can legitimately be referred to as the foundation of every PCB design. Just like the way in which PCBs do, pins function like the interconnect system in addition to numerous plug-in purposes. The circuit board design does certainly have a big amount of functionality thanks to hooks. Circuit board pins may be pushed in to circuit, swaged, and, for most circumstances, soldered it to Circuit board to be able to attach them to it. A crucial conductive channel for the electrical circuit is offered by PCB pins. As the mechanical interface, it offers an meeting module strength. What are the Common PCB connector varieties? How Can PCB Connector Be Tested? In order to connect two elements and perhaps a circuit board electrically, PCB header pins is continuously employed. Although there are quite a few totally different kinds of PCB header pins, they’re sometimes male connectors organized inside a row and spaced apart by a set distance and vary.

The PCB pins can legitimately be referred to as the foundation of every PCB design. Just like the way in which PCBs do, pins function like the interconnect system in addition to numerous plug-in purposes. The circuit board design does certainly have a big amount of functionality thanks to hooks. Circuit board pins may be pushed in to circuit, swaged, and, for most circumstances, soldered it to Circuit board to be able to attach them to it. A crucial conductive channel for the electrical circuit is offered by PCB pins. As the mechanical interface, it offers an meeting module strength. What are the Common PCB connector varieties? How Can PCB Connector Be Tested? In order to connect two elements and perhaps a circuit board electrically, PCB header pins is continuously employed. Although there are quite a few totally different kinds of PCB header pins, they’re sometimes male connectors organized inside a row and spaced apart by a set distance and vary. What’s a Board to Board Connectors? As its title suggests, it’s a connector that connects boards to boards. It’s also called Board to Board Connector, board-to-board connector, and many others. It started with a pin (called a pin header) that stands on the board and a socket into which it is inserted. Since then, Board to Board Connectors of various shapes have appeared in response to numerous applications and dimension requirements. In comparison with instances where connections are made through wires or FPC / FFC, the connections are neat and compact. Board to Board Connectors have three kinds of connections relying on the combination of these. Boards may be related in parallel by utilizing ST type for each Socket. If one of the boards becomes a child board, it is named a mezzanine connection, and so forth., as if it had been a two-story structure. Connectors for Stacking connection are therefore additionally referred to as mezzanine connectors.

What’s a Board to Board Connectors? As its title suggests, it’s a connector that connects boards to boards. It’s also called Board to Board Connector, board-to-board connector, and many others. It started with a pin (called a pin header) that stands on the board and a socket into which it is inserted. Since then, Board to Board Connectors of various shapes have appeared in response to numerous applications and dimension requirements. In comparison with instances where connections are made through wires or FPC / FFC, the connections are neat and compact. Board to Board Connectors have three kinds of connections relying on the combination of these. Boards may be related in parallel by utilizing ST type for each Socket. If one of the boards becomes a child board, it is named a mezzanine connection, and so forth., as if it had been a two-story structure. Connectors for Stacking connection are therefore additionally referred to as mezzanine connectors.