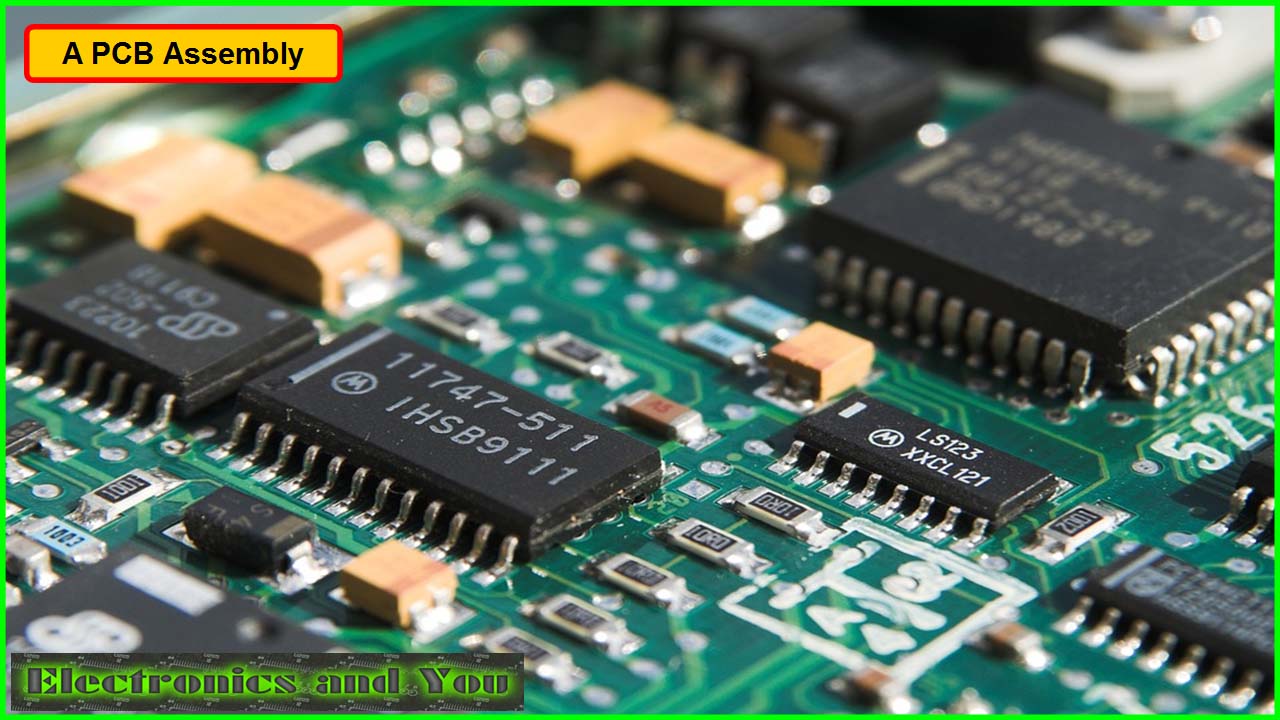

Nowadays printed circuit boards have become synonymous to digital units. Such board varies vastly from their design to their capabilities. And thus if you are literally hiring any company for designing and pcba manufacturing your circuit boards care must be taken about the quality and product of work they’re supplying. So for all you newbies out there starting off on this planet of digital units this is your 101 checklist to think about earlier than hiring any PCB manufacturing company. If you find yourself hiring any flexible circuit board manufacturers step one is to test their experiences. Remember regardless of how a lot begin-studded the educational career be a new company will take their time in designing your prototype. Designing actual-life prototypes are a unique style of games and thus if you are in hurry together with your flex PCB board it is always advisable that you just choose any experienced company with growing and deploying prototypes for a number of gadgets and in multiple domains. However, if you’re a lover of all that’s is experimental and on the lookout for some game-altering concepts and never agile prototyping then selecting new businesses beaming with inventive concepts may be your right choose.

The world of Flexi circuit boards are large and huge. PCB boards are a fancy field the place a variety of circuits are built-in and chipped for creating compact boards of assorted fashionable high-end circuit devices. So whereas hiring versatile circuit boards manufacturers checking their expertise is fine however make sure that their skills tallies up along with your discipline of digital units is even more vital. Remember hiring experienced companies with talents that do not tallies up along with your needs might end in heavy loss. Technology is an ever-changing domain. And all related companies ought to carry on updating themselves with the newer inclusions. PCB manufacturing business can be no totally different. So when you find yourself choosing up your manufacturing company keep in mind that they are going to be your peer for designing the prototype. So be sure that the manufacturing company you are deciding on is at par all the latest technologies and uses the identical for designing your prototype.

The world of Flexi circuit boards are large and huge. PCB boards are a fancy field the place a variety of circuits are built-in and chipped for creating compact boards of assorted fashionable high-end circuit devices. So whereas hiring versatile circuit boards manufacturers checking their expertise is fine however make sure that their skills tallies up along with your discipline of digital units is even more vital. Remember hiring experienced companies with talents that do not tallies up along with your needs might end in heavy loss. Technology is an ever-changing domain. And all related companies ought to carry on updating themselves with the newer inclusions. PCB manufacturing business can be no totally different. So when you find yourself choosing up your manufacturing company keep in mind that they are going to be your peer for designing the prototype. So be sure that the manufacturing company you are deciding on is at par all the latest technologies and uses the identical for designing your prototype.

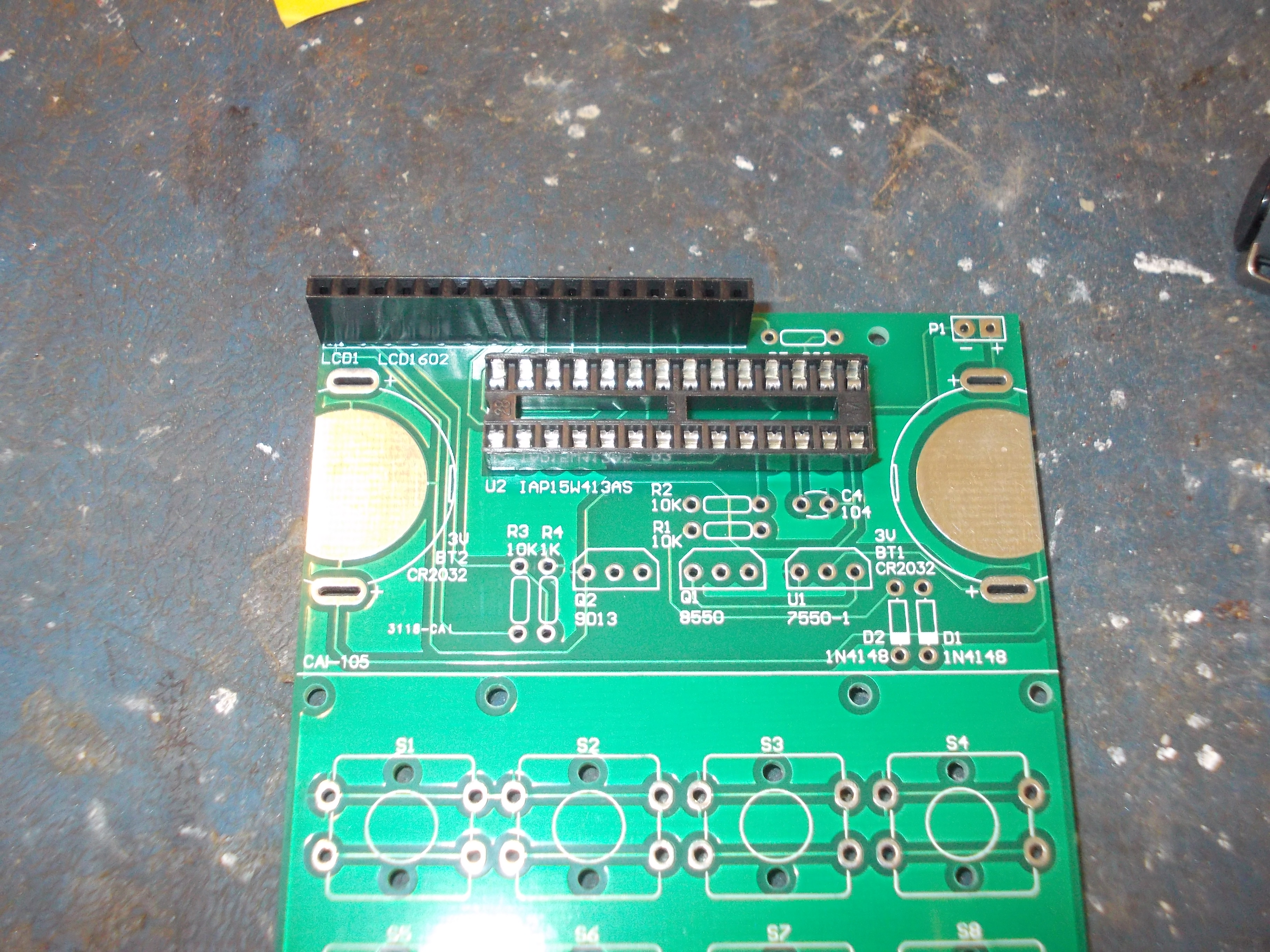

The flexibility to customizing the prototype design has always been an interesting quality. Sometimes regardless of how much completely you design the prototype there are some traces or loops left within the design. Also at occasions, you are feeling like improvising the design at such times make certain your manufacturing friends know how to include those add-ons. Remember the terms of services varies from company to firm. However, it’s all the time greatest to choose those who present you a comprehensive service. Sometimes after building the prototype there appear some loops within the design which must be fastened. It’s at all times best to choose those firms who cover for fixing all the faults publish prototype supply. Apart from these vital ones guantee that the agency you choose have a fame across the nation, together with software proficiency and experience over a various vary of PCB creation. So examine all the requisites stringently and select your PCB friends now.

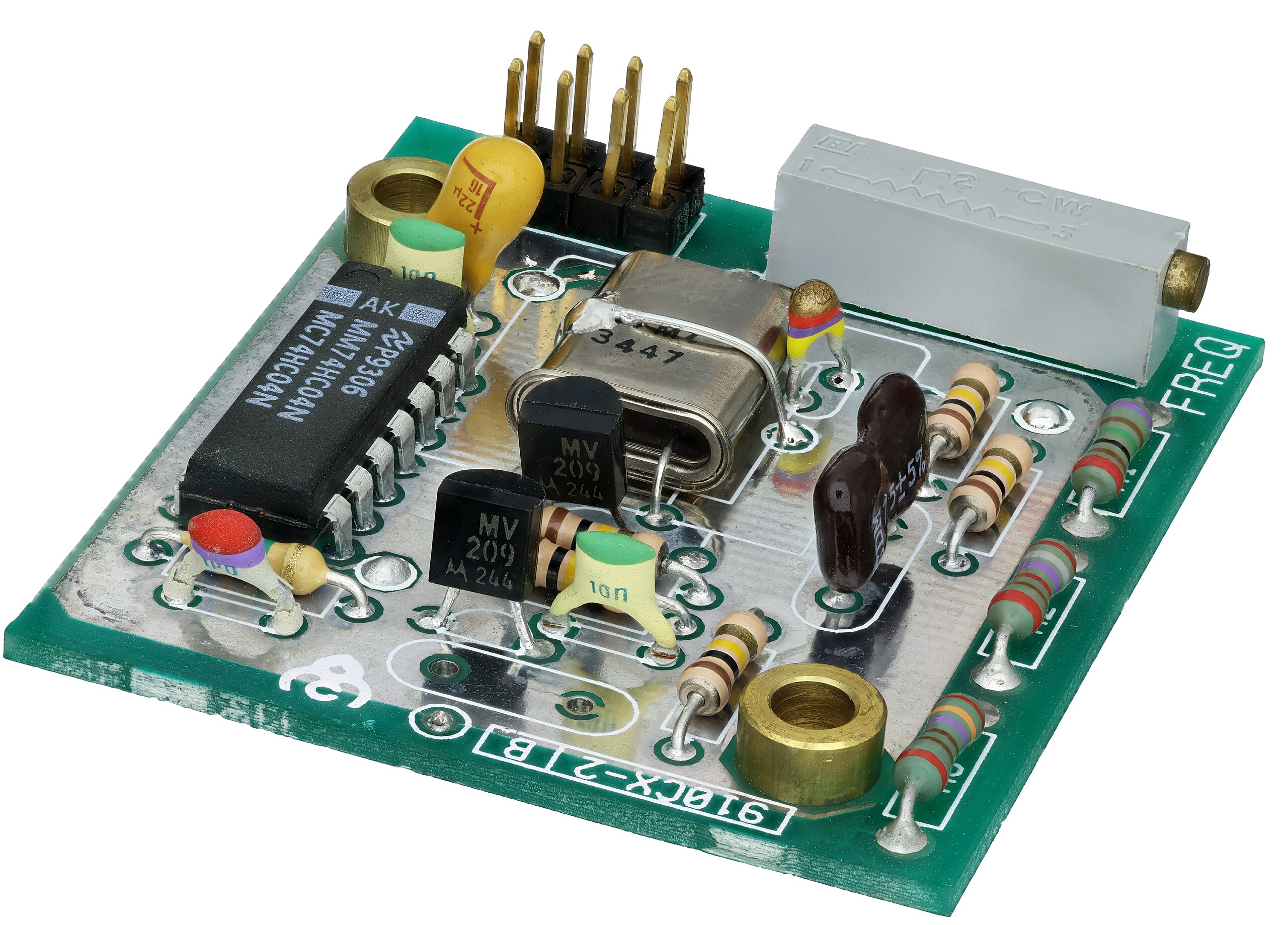

The method by which the naked printed circuit boards, PCBs utilized in electronic products is evey bit as vital as the assembling with elements. PCB manufacture fundamentals How to decide on the best PCB manufacturer The PCB manufacturing process is very important for anybody involved within the electronics trade. Printed circuit boards, PCBs, are very extensively used as the premise for digital circuits. Printed circuit boards are used to supply the mechanical basis on which the circuit could be constructed. Accordingly virtually all circuits use printed circuit boards and they are designed and utilized in portions of hundreds of thousands. Although PCBs form the idea of nearly all electronic circuits as we speak, they are typically taken without any consideration. Nevertheless technology on this space of electronics is transferring forward. Track sizes are reducing, the numbers of layers within the boards is growing to accommodate for the elevated connectivity required, PCB assembly and the design guidelines are being improved to make sure that smaller SMT devices may be handled and the soldering processes utilized in manufacturing will be accommodated.

The PCB manufacturing process may be achieved in a selection of ways and there are quite a lot of variants. Despite the various small variations, the main phases within the PCB manufacturing course of are the same. Printed circuit boards, PCBs, might be made from a wide range of substances. The most generally used in a form of glass fibre based board often known as FR4. If you liked this informative article and you desire to get more details about pcb assembly, visit the following website, generously check out the internet site. This provides an affordable diploma of stability under temperature variation and is doesn’t breakdown badly, whereas not being excessively expensive. Other cheaper supplies are available for the PCBs in low cost industrial merchandise. For prime efficiency radio frequency designs where the dielectric constant of the substrate is essential, and low ranges of loss are needed, then PTFE primarily based printed circuit boards can be used, though they are far harder to work with. In an effort to make a PCB with tracks for the components, copper clad board is first obtained. This consists of the substrate material, usually FR4, with copper cladding usually on each sides.

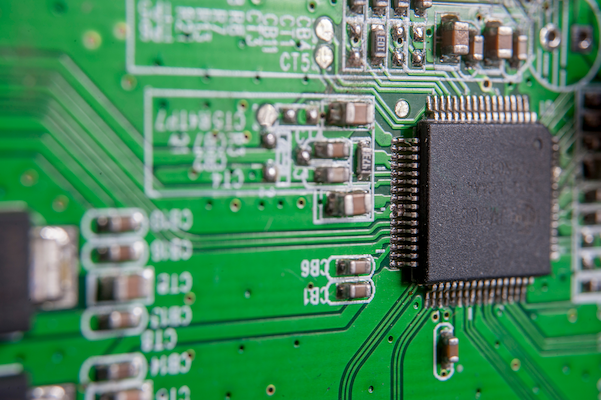

Printed circuit board (PCB) inspection is a important step in ensuring quality and reliability across the electronics manufacturing course of. Both bare boards and assembled PCBs should be fastidiously examined to validate acceptability earlier than shipment to customers. But what particular criteria represent a proper PCB inspection? Read on for an overview of inspection targets, standards, metrics, tools, and key defect varieties checked during the PCB inspection course of. Thorough inspection in opposition to established standards minimizes transport defective boards to prospects. Manufacturers generally define an inspection plan with accept/reject criteria mapped to these standards. IPC standards particularly provide a framework for deciphering the severity of certain defects. Tracking metrics gives knowledge to constantly enhance processes and product high quality over time. Automated Optical Inspection (AOI) – Imaging system scans boards at high decision capturing any defects. Computer algorithms analyze images towards CAD information to detect discrepancies. Solder Mask Inspection – Validating uniformity and accuracy of solder mask utility. Checking for voids, skinny areas, misregistration.

Printed circuit board (PCB) inspection is a important step in ensuring quality and reliability across the electronics manufacturing course of. Both bare boards and assembled PCBs should be fastidiously examined to validate acceptability earlier than shipment to customers. But what particular criteria represent a proper PCB inspection? Read on for an overview of inspection targets, standards, metrics, tools, and key defect varieties checked during the PCB inspection course of. Thorough inspection in opposition to established standards minimizes transport defective boards to prospects. Manufacturers generally define an inspection plan with accept/reject criteria mapped to these standards. IPC standards particularly provide a framework for deciphering the severity of certain defects. Tracking metrics gives knowledge to constantly enhance processes and product high quality over time. Automated Optical Inspection (AOI) – Imaging system scans boards at high decision capturing any defects. Computer algorithms analyze images towards CAD information to detect discrepancies. Solder Mask Inspection – Validating uniformity and accuracy of solder mask utility. Checking for voids, skinny areas, misregistration. How does automated optical inspection (AOI) work? AOI compares pictures of board options to CAD data using subtle algorithms to determine discrepancies in the location, assembly, and soldering revealing any defects. Does PCB inspection impression manufacturing price? Automated inspection integrates inline without slowing general price. Manual inspection can turn into a bottleneck. AOI presents 10x the inspection factors per hour in comparison with manual. What info should PCB inspection reviews contain? Reports convey photos/details of every defect discovered, measurement knowledge, defect counts, process functionality metrics, repair suggestions, and cross/fail standing relative to acceptance standards. Rigorous PCB (

How does automated optical inspection (AOI) work? AOI compares pictures of board options to CAD data using subtle algorithms to determine discrepancies in the location, assembly, and soldering revealing any defects. Does PCB inspection impression manufacturing price? Automated inspection integrates inline without slowing general price. Manual inspection can turn into a bottleneck. AOI presents 10x the inspection factors per hour in comparison with manual. What info should PCB inspection reviews contain? Reports convey photos/details of every defect discovered, measurement knowledge, defect counts, process functionality metrics, repair suggestions, and cross/fail standing relative to acceptance standards. Rigorous PCB ( Printed circuit board (PCB) inspection is a critical step in making certain quality and reliability throughout the electronics manufacturing course of. Both naked boards and assembled PCBs must be rigorously examined to validate acceptability before shipment to customers. But what specific criteria constitute a correct PCB (

Printed circuit board (PCB) inspection is a critical step in making certain quality and reliability throughout the electronics manufacturing course of. Both naked boards and assembled PCBs must be rigorously examined to validate acceptability before shipment to customers. But what specific criteria constitute a correct PCB ( How does automated optical inspection (AOI) work? AOI compares pictures of board features to CAD data using subtle algorithms to determine discrepancies in the location, assembly, and soldering revealing any defects. Does PCB inspection impact manufacturing fee? Automated inspection integrates inline without slowing overall rate. Manual inspection can turn out to be a bottleneck. AOI affords 10x the inspection points per hour compared to guide. What information ought to PCB inspection studies include? Reports convey images/details of each defect discovered, measurement data, defect counts, process functionality metrics, restore recommendations, and move/fail standing relative to acceptance criteria. Rigorous PCB inspection towards established acceptability criteria ensures quality and reliability. Both naked boards and assembled PCBs undergo extensive automated optical, electrical, and useful verification using metrics outlined by requirements. Passing scrutiny throughout parameters like soldering, components, board fabrication, and

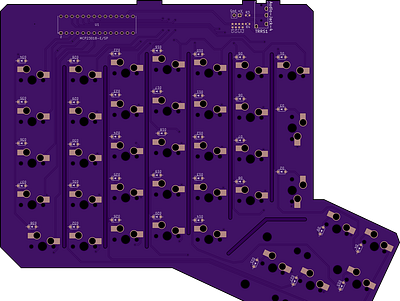

How does automated optical inspection (AOI) work? AOI compares pictures of board features to CAD data using subtle algorithms to determine discrepancies in the location, assembly, and soldering revealing any defects. Does PCB inspection impact manufacturing fee? Automated inspection integrates inline without slowing overall rate. Manual inspection can turn out to be a bottleneck. AOI affords 10x the inspection points per hour compared to guide. What information ought to PCB inspection studies include? Reports convey images/details of each defect discovered, measurement data, defect counts, process functionality metrics, restore recommendations, and move/fail standing relative to acceptance criteria. Rigorous PCB inspection towards established acceptability criteria ensures quality and reliability. Both naked boards and assembled PCBs undergo extensive automated optical, electrical, and useful verification using metrics outlined by requirements. Passing scrutiny throughout parameters like soldering, components, board fabrication, and  There are important selections and concerns to make for a profitable inflexible-flex PCB design course of at an early stage. These are important if you happen to want to keep up its reliability and reduce prices. Are you a inflexible-flex PCB designer searching for some design principles? This text is for you. What is Rigid-Flex PCB? Rigid-Flex PCB is a board that combines inflexible board applied sciences and flexible circuits. The manufacturing course of tends to be much like a conventional hardboard circuit, however some layers are versatile circuitry working throughout the hardboard. Many rigid-flex boards have a number of flexible circuit substrates layers connected to either a number of rigid boards. This can also be internally or externally relying n the kind of design utilized in the appliance. The flexible circuit substrates are designed to keep up a relentless state formed into flexed curves throughout installation or manufacturing. Rigid-flex PCB designs are extra challenging than the everyday inflexible board surroundings because the boards are made in a 3D space with greater spatial effectivity.

There are important selections and concerns to make for a profitable inflexible-flex PCB design course of at an early stage. These are important if you happen to want to keep up its reliability and reduce prices. Are you a inflexible-flex PCB designer searching for some design principles? This text is for you. What is Rigid-Flex PCB? Rigid-Flex PCB is a board that combines inflexible board applied sciences and flexible circuits. The manufacturing course of tends to be much like a conventional hardboard circuit, however some layers are versatile circuitry working throughout the hardboard. Many rigid-flex boards have a number of flexible circuit substrates layers connected to either a number of rigid boards. This can also be internally or externally relying n the kind of design utilized in the appliance. The flexible circuit substrates are designed to keep up a relentless state formed into flexed curves throughout installation or manufacturing. Rigid-flex PCB designs are extra challenging than the everyday inflexible board surroundings because the boards are made in a 3D space with greater spatial effectivity. Since it is potential to design in three dimensions, it is simple for designers to twist, fold or roll the versatile substrates to achieve the specified last form. The trendy technology is properly improved in relation to the production of giant-scale portions PCB assembly and PCB fabrication or production of a inflexible-flex prototype. The flex PCB process is sweet in overcoming weight and house issues. Careful consideration of rigid-flex solutions and correct evaluation of the various choices available is thought to have significant benefits. The PCB (

Since it is potential to design in three dimensions, it is simple for designers to twist, fold or roll the versatile substrates to achieve the specified last form. The trendy technology is properly improved in relation to the production of giant-scale portions PCB assembly and PCB fabrication or production of a inflexible-flex prototype. The flex PCB process is sweet in overcoming weight and house issues. Careful consideration of rigid-flex solutions and correct evaluation of the various choices available is thought to have significant benefits. The PCB (